This page features dissemination and communication materials of DryFiciency project that may be of interest to partners and other stakeholders. They are available for download below. Finally, some impressions from our stakeholders are presented at the bottom.

DryFiciency Flyers & Posters

DryFiciency General presentation

DryFiciency Infographics

DryFiciency Videos

1. DryFiciency Demonstration at Wienerberger plant Austria - watch the video here!

2.New DryFiciency video - watch the video on our YouTube channel!

3. First DryFiciency animation video - click here to watch on YouTube!

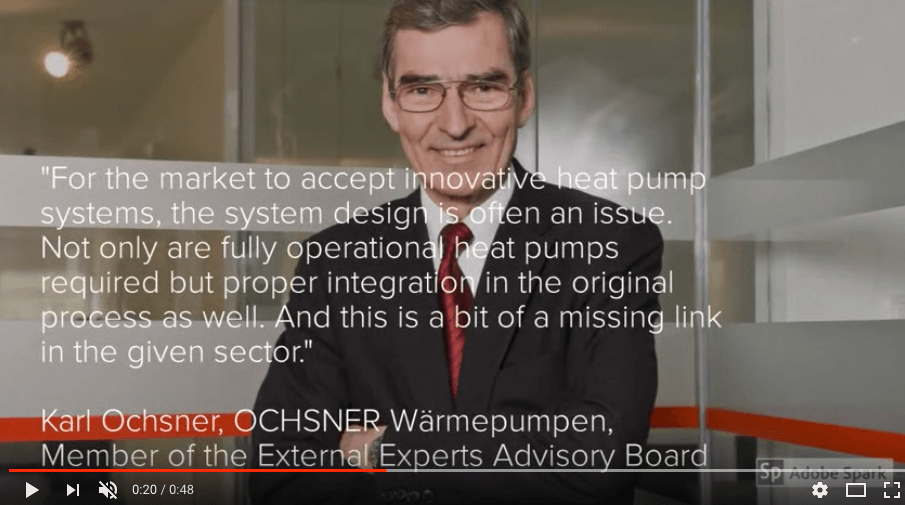

4. Testimonials from stakeholders - click here to watch on YouTube!

Impressions from our stakeholders

Impressions from our stakeholders

„To increase energy efficiency in EU’s industry, the utilization of otherwise unused waste heat is one of the most important drivers to reduce CO2 emissions. The DryFiciency project will demonstrate three pilot instalations to apply innovative high-temperature heat pumps to reduce the carbon emissions and energy costs in industrial drying processes at the sites of Wienerberger, Agrana and Mars. The newly developed heat pump technology, supplying up to 160°C, will then be ready to be implemented in other sectors as well to contribute to a clean, innovative and competitive EU industry.“

Michael Hartl, former DryFiciency project coordinator at Austrian Institute of Technology

Impressions from our stakeholders

Impressions from our stakeholders

“We see a potential in using closed loop heat pump technology in all drying applications of extruded products such as pet food and aqua feed. Heat pump technology is very much capable of replacing gas burners in these types of applications. The biggest contribution of research institutions for their market acceptance could be to keep searching for ways to drive down the cost of components of heat pumps or heat pumps themselves. “

Sander Geelen, Geelen Counterflow